Pennekamp 4500 mm -49%

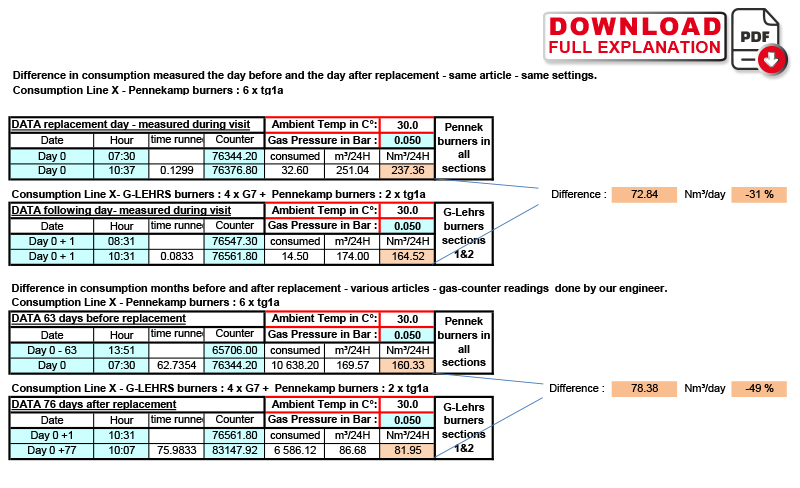

REPLACING BURNERS IN A PENNEKAMP LEHR – BELTWIDTH : 4 500 mm CONSUMPTION : before replacing : 237 Nm3 / day – after replacing : 165 Nm³ / day

| OLD CONFIGURATION | NEW CONFIGURATION | ||

|---|---|---|---|

| Section 1 : | 2 Burners tg1a | Replaced by : | 2 Burners G-Lehrs G7 |

| Section 2 : | 2 Burners tg1a | Replaced by : | 2 Burners G-Lehrs G7 |

| Section 3 : | 1 Burner tg1a | Unchanged : | 1 Burner tg1a |

| Section 4 : | 1 Burner tg1a | Unchanged : | 1 Burner tg1a |

- For every new client we make a study (for free) of the client’s situation and calculate the possible gain in consumption for the running article.

- We visited this factory 2 months before ‘Day 0’ (day of replacement) and our study calculated a possible gain of 28 %.

- Replacing is done without stopping the production. At the installation day the gain was 31 %, but the article and settings were different.

- Replacing 4 burners started on ‘Day 0’ at 11H00 and took 3 hours : 1 hour for the first one and 2 hours for the 3 following.

- The production was never interrupted – burners were replaced one by one.

Please meet us at GLASSTEC 22-25 Oct 24 – G-LEHRS by MU – Hall 14 / G44

REALISATION & RESULTS

BURNERS :![]() G5

G5![]() –

–![]() G6

G6 ![]() –

–![]() G7

G7![]() –

–![]() G9

G9

HOME ![]() –

– ![]() ELECTRIC HEATERS

ELECTRIC HEATERS ![]() –

– ![]() CONTACT

CONTACT